YT27 rock drill: efficient, flexible, durable and versatile, helping mines, tunnels and construction projects to operate efficiently

YT27 air-leg rock drill is mainly used for rock drilling in mine tunnel excavation. It is also a widely used rock drilling tool in railway, water conservancy and national defense stone engineering.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Model Number: |

YT27 |

Certification: |

Provide |

Commercial terms of Products

Minimum Order Quantity: |

15 |

Price: |

200-290$/set |

Packaging Details: |

Plywood box, calcium plastic box, Boutique plywood case |

Delivery Time: |

7-15 days |

Payment Terms: |

T/T |

Supply Ability: |

100 units per month |

Description

YT27 air-leg rock drill is mainly used for rock drilling in mine tunnel excavation. It is also a widely used rock drilling tool in railway, water conservancy and national defense stone engineering. It can be used with FY250 oiler and FT160A (or FT160B, FT160C, FT170) air legs to perform wet rock drilling on medium-hard and hard rocks, and drill horizontal and inclined blastholes. It can also be installed on a trolley for use after removing the air legs.

Applications

1. Mining

Open-pit and underground mines: The YT27 rock drill is often used for drilling operations in mining and for drilling blasting holes. Whether it is an open-pit mine or an underground mine, it can efficiently complete the drilling task of medium-hard to hard rocks.

2. Tunnel engineering

Railway and highway tunnels: During the excavation of railway and highway tunnels, the YT27 rock drill is used to drill blasting holes and anchor holes to help quickly advance tunnel excavation.

Water conservancy tunnels: In water conservancy projects, such as the excavation of water diversion tunnels and drainage tunnels, the YT27 rock drill also plays an important role.

3. Construction engineering

Foundation engineering: In the construction of building foundations, the YT27 rock drill is used to drill rock foundations to provide conditions for the foundation construction of buildings.

Foundation pit excavation: During the excavation of deep foundation pits, the YT27 rock drill is used to drill rock layers to facilitate subsequent excavation and support operations.

4. Quarry

Stone mining: In the quarry, the YT27 rock drill is used to drill holes for stone mining and help separate large pieces of stone for subsequent cutting and processing.

Competitive Advantage:

1. Efficient rock drilling

Powerful impact force: The YT27 rock drill uses advanced pneumatic technology to provide powerful impact force, which can quickly drill medium-hard to hard rocks and significantly improve operating efficiency.

High drilling speed: Due to its efficient impact system and optimized structural design, the YT27 rock drill can drill faster than other similar equipment under the same conditions, shortening the engineering cycle.

2. Flexible and lightweight

Compact design: The YT27 rock drill has a compact structure and light weight, which is easy to operate and move, and is suitable for use in narrow and complex working environments.

Flexible operation: The equipment is humanized in design, simple to operate, and can adapt to a variety of working angles and positions, which improves the flexibility and adaptability of the operation.

3. Strong durability

High-quality materials: Key components are made of high-strength, wear-resistant and corrosion-resistant materials, ensuring the long-term and stable operation of the equipment in harsh working environments.

Long Service life: The YT27 rock drill has undergone strict quality control and durability testing, has a long service life, and reduces the frequency of equipment replacement and maintenance.

4. Ease of use and easy maintenance

Easy operation: The YT27 rock drill has a user-friendly design, an intuitive operating interface, and is easy to use, reducing the training cost and time of operators.

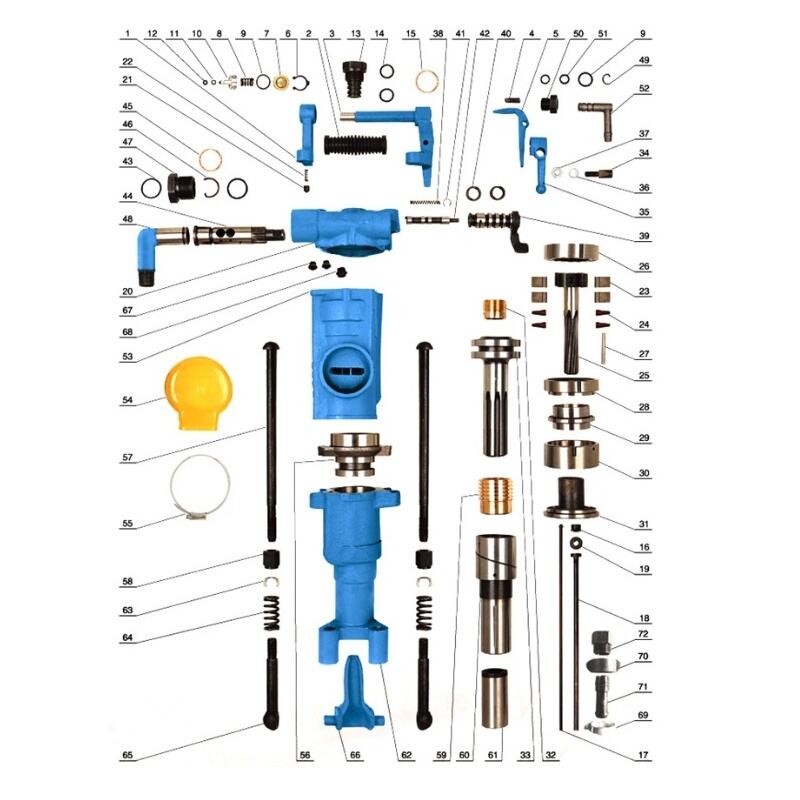

Easy maintenance: The equipment has a reasonable structure design, simple maintenance, and easy disassembly and replacement of key components, which reduces maintenance costs and downtime.

5. Economical

High cost performance: While providing high efficiency and durability, the YT27 rock drill has a relatively reasonable price and high cost performance, making it suitable for small and medium-sized enterprises and large engineering projects.

Low operating cost: Due to its efficient rock drilling performance and low maintenance cost, the overall operating cost of the YT27 rock drill is low, saving users a lot of operating expenses.

6. Wide range of application areas

Versatility: The YT27 rock drill is suitable for a variety of operating environments, including mining, tunnel engineering, construction engineering, quarries, geological exploration, water conservancy engineering, municipal engineering and military engineering, etc., and has a wide range of application prospects.

Strong adaptability: The equipment can adapt to different rock conditions and operating requirements, showing good adaptability and reliability.

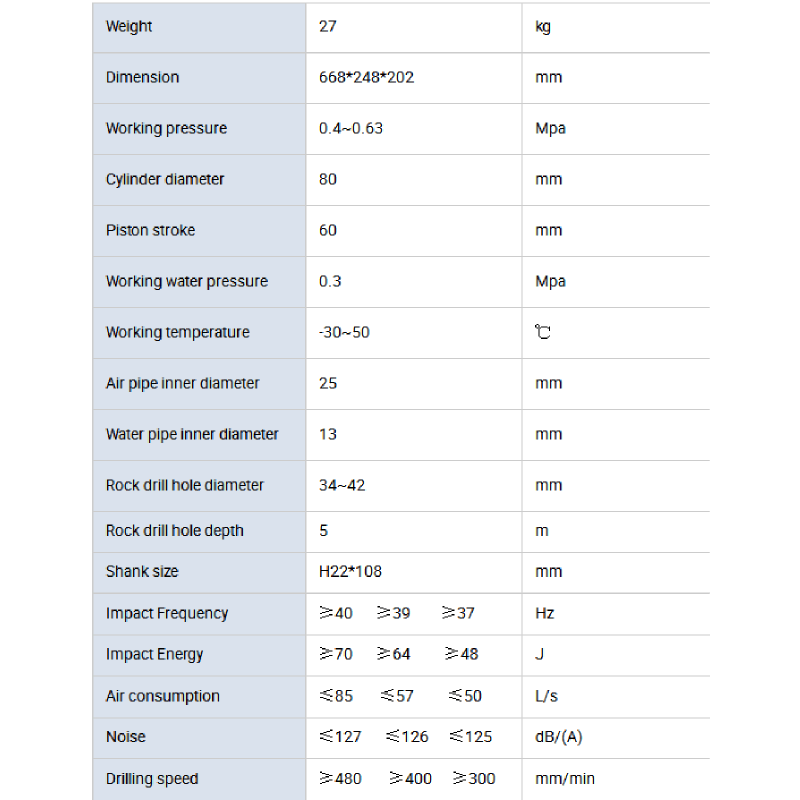

Specifications

| YT27 AIR LEG ROCK DRILL | ||||||

| Weight | 27 | kg | ||||

| External Dimensions (L W H) | 668X248X202 | mm | ||||

| Working Air Pressure | 0.4-0.63 | MPa | ||||

| Cylinder Diameter | 80 | mm | ||||

| Piston Structure Stroke | 60 | mm | ||||

| Working Water Pressure | 0.3 | MPa | ||||

| Working Temperature | -30~50 | ℃ | ||||

| Air Pipe Inner Diameter | 25 | mm | ||||

| Water Pipe Inner Diameter | 13 | mm | ||||

| Suitable Drilling Diameter | 34~42 | mm | ||||

| Suitable Max Drilling Depth | 5 | m | ||||

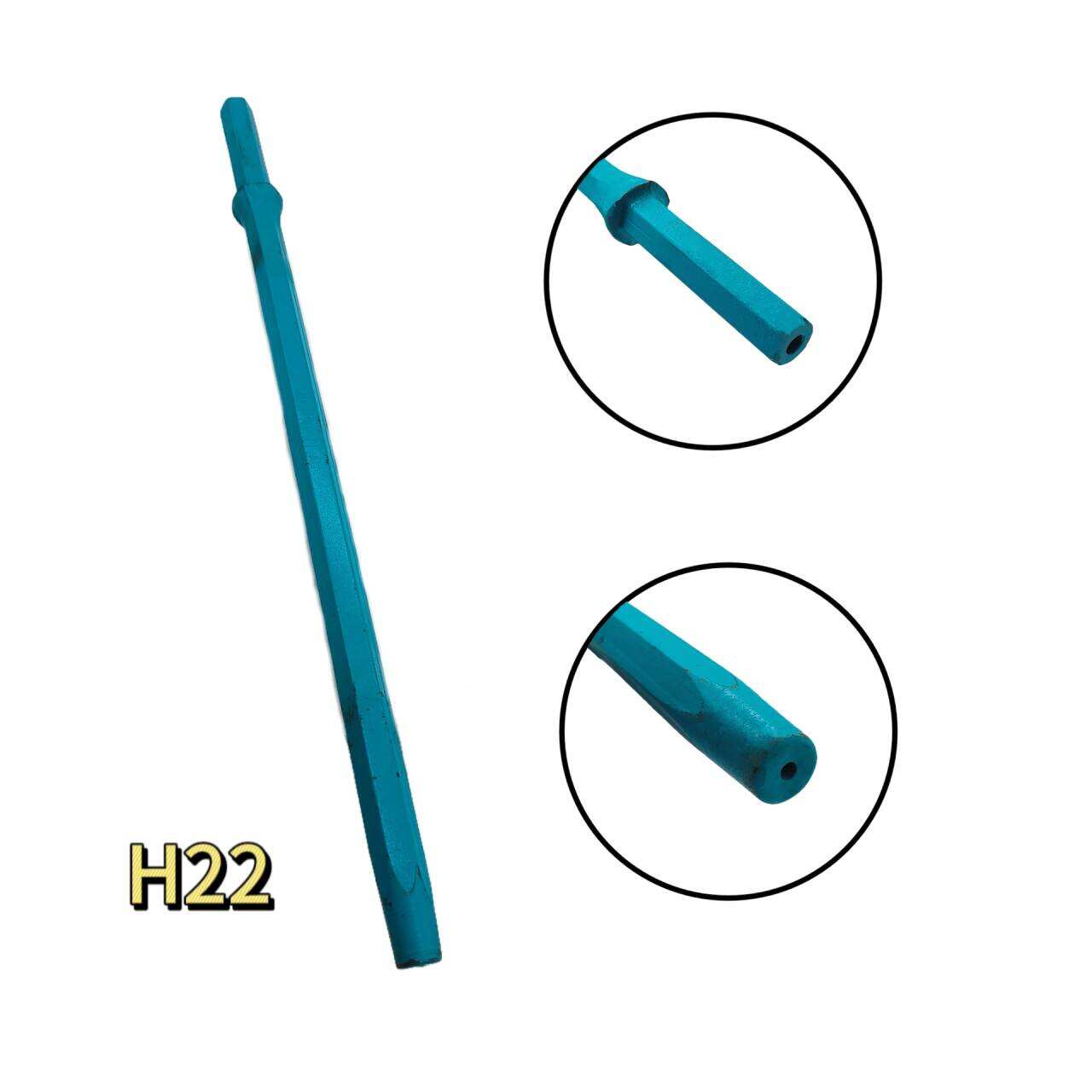

| Shank Size | H22X108 | mm | ||||

| Acceptance Of Air Pressure | 0.63 0.5 0.4 | MPa | ||||

| Impact Frequency Of Rock Drill | ≥40 ≥39 ≥37 | Hz | ||||

| Impact Energy | ≥70 ≥64 ≥48 | J | ||||

| Noise | ≤127 ≤126 ≤125 | Db/(A) | ||||

| Drilling Speed | ≥480 ≥400 ≥300 | mm/min | ||||

| FY250 Model Oil Lubricator | ||||||

| Weight | 1.2 | kg | ||||

| Oil Capacity | 0.25 | L | ||||

| Air leg | ||||||

| Model | FT160A | FT160B | FT160C | |||

| Weight | 17 | 15 | 18 | kg | ||

| Length | 1668 | 1428 | 1820 | mm | ||

| Propulsion Stroke | 1338 | 1098 | 1490 | mm | ||

| Cylinder Inner Diameter | 65 | 65 | 65 | mm | ||