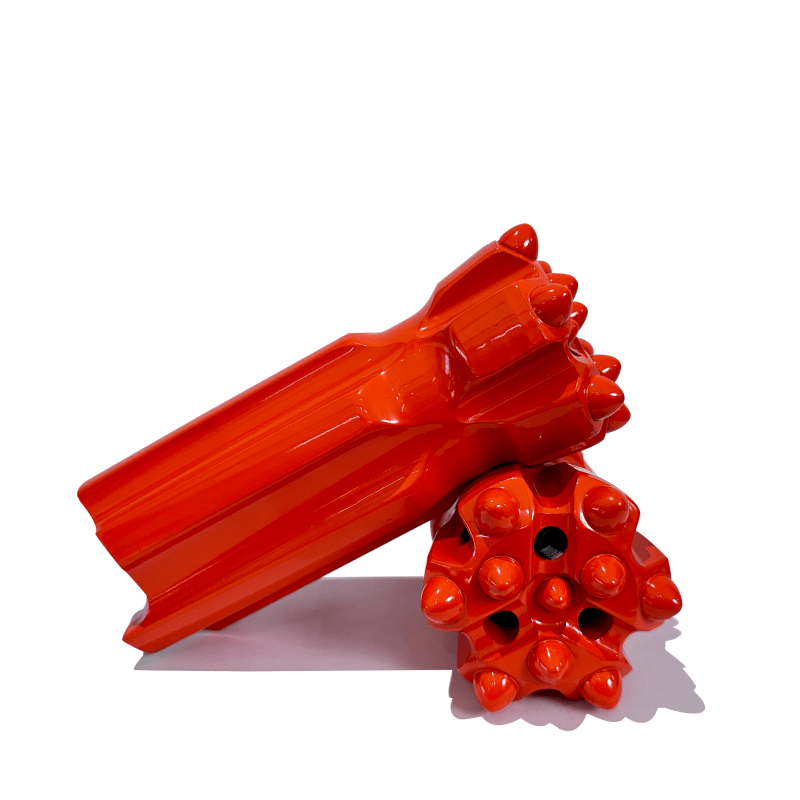

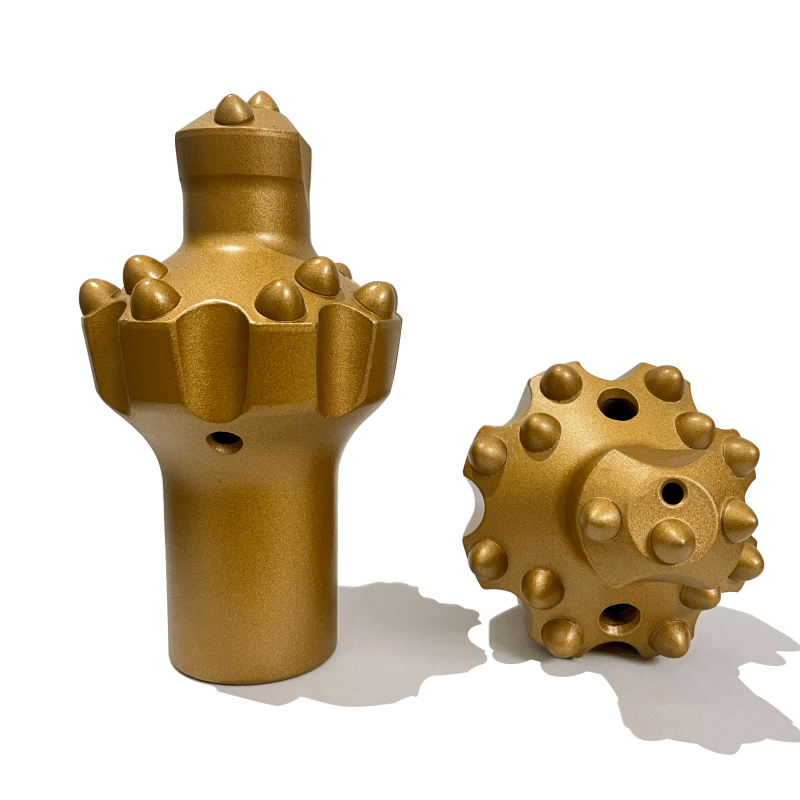

High Quality R25 R32 R38 T38 T45 T51 Rock Drilling Tools Threaded Button Bits Used in Mines

A threaded drill bit is a tool used for drilling and rock breaking, and is commonly used in mining, construction, geological exploration, and other fields. It is usually inlaid with carbide teeth or diamonds to improve wear resistance and breaking efficiency.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Thread Type: |

R25/R28/R32/R3212/R38/HL38/T38/T45/T51/T60/ST58/ST68 |

Bit diameter: |

33mm--152mm |

|

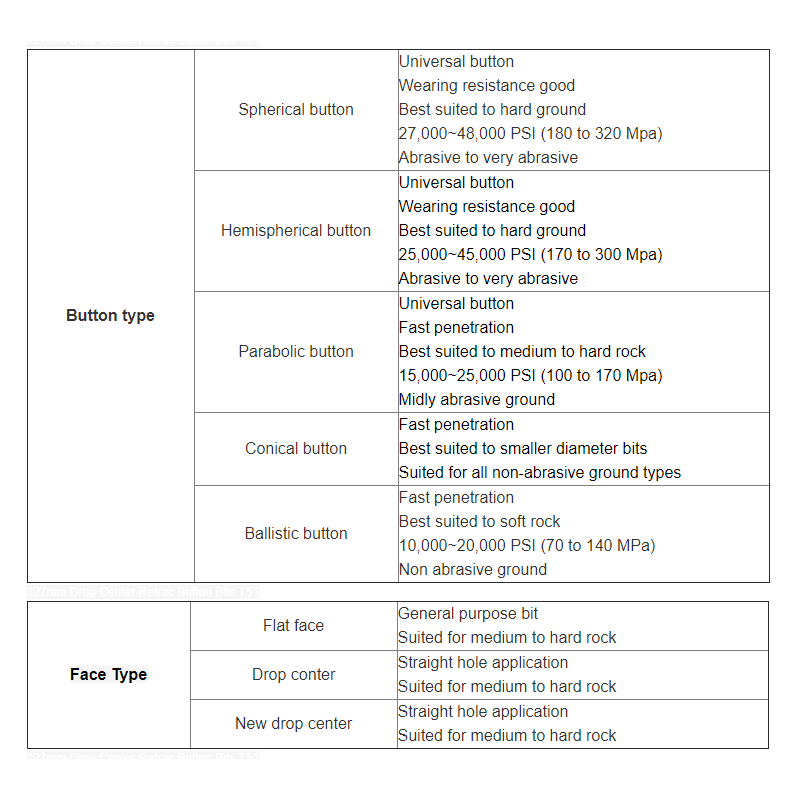

Bit face design:

|

Flat face、Drop center、New drop center 、Reaming、Dome |

|

Button shape

|

Spherical、Parabolic、Conical、Ballistic |

Commercial terms of Products

Minimum Order Quantity: |

5 pieces |

Price: |

70~180$ |

Packaging Details: |

Plastic boxes, wooden boxes, cartons, etc. |

Delivery Time: |

7~20days |

Payment Terms: |

T/T |

Supply Ability: |

customize |

Description:

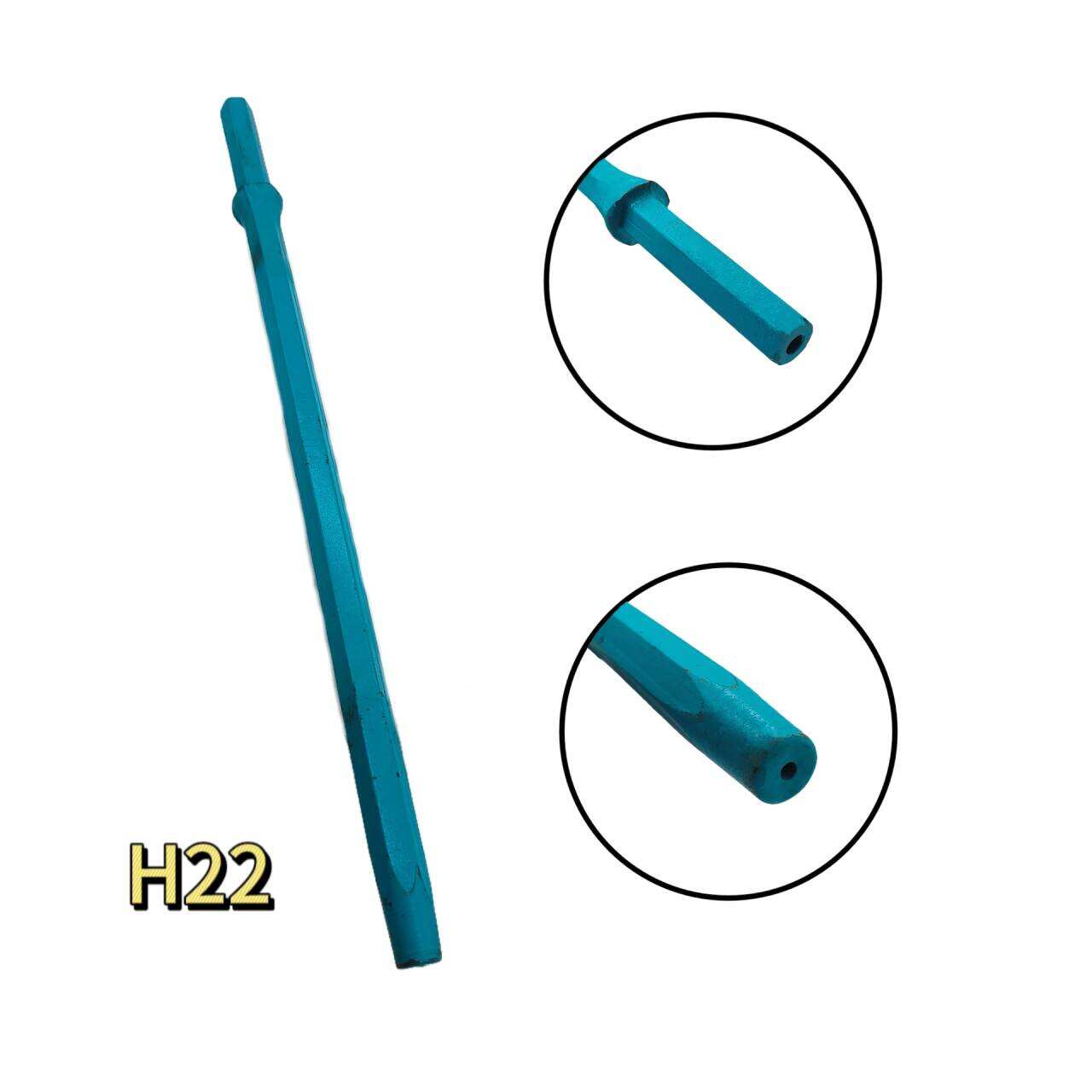

A threaded drill bit is a tool used for drilling and rock breaking, and is commonly used in mining, construction, geological exploration, and other fields. It is usually inlaid with carbide teeth or diamonds to improve wear resistance and breaking efficiency. The threaded part is used to connect the Drill Rod or drill pipe, ensuring that the drill bit can be firmly fixed on the drill tool and transmit rotational force and impact.

Applications:

1.Mining: used for mining ore and coal, and drilling blast holes.

2.Construction: used for foundation engineering, tunneling, and rock crushing.

3.Geological exploration: used for drilling geological samples to understand underground structures and resource distribution.

Competitive Advantage:

1. High efficiency

The drill bit inlaid with carbide or diamond has a very high crushing ability and can complete a lot of work in a short time.

2. Durability

After special heat treatment and precision processing, the threaded drill bit has good impact resistance and can remain stable in harsh working environments.

3. Adaptability

There are many types of threaded Drill Bits (such as straight, cross, ball tooth, diamond, etc.), which can adapt to rocks and geological conditions of different hardness. It is suitable for mining, construction, geological exploration and other fields, and has a wide range of applications.

5. Connection stability

The thread design ensures a firm connection between the drill bit and the drill rod or drill rod, and the transmission of rotational force and impact force is more stable. The stable connection reduces vibration during work and improves drilling accuracy and operational safety.

6. Chip removal performance

The well-designed chip removal groove can effectively discharge the rock chips and debris generated during the drilling process, keeping the drilling clean and efficient. Good chip removal performance reduces the risk of drilling blockage and improves work efficiency.