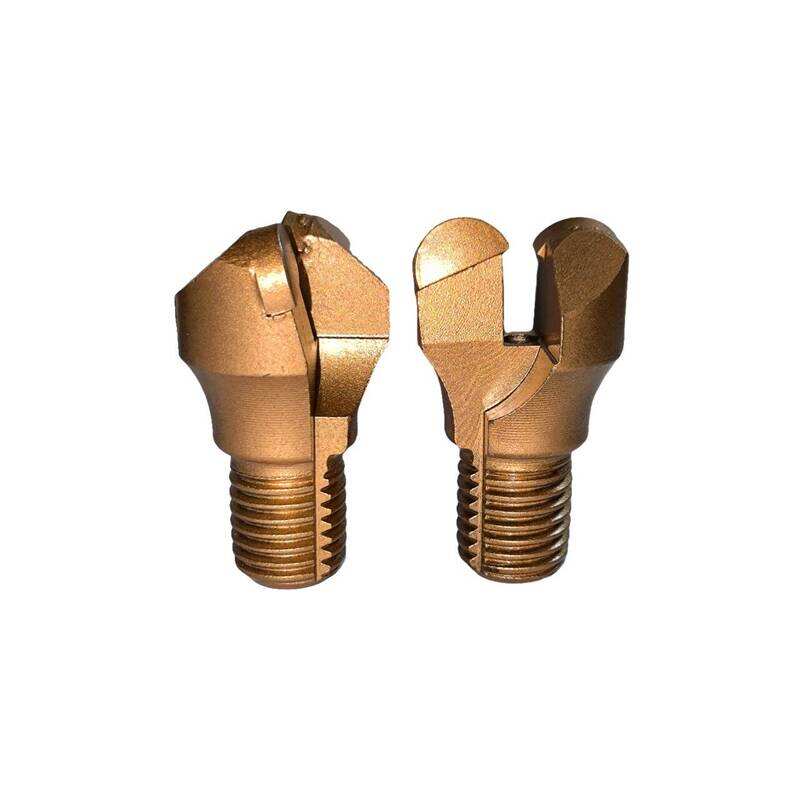

Various specifications of PDC anchor drill bits can be customized for wholesale

PCD anchor drill bit is a high-performance drilling tool designed for challenging materials such as reinforced concrete, abrasive rock, and other hard substrates.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Model Number: |

PDC Anchor drill bit |

Certification: |

Provide |

Common diameter |

28mm,30mm,32mm,34mm,36mm,38mm,40mm,42mm,45mm |

Commercial terms of Products

Minimum Order Quantity: |

20 |

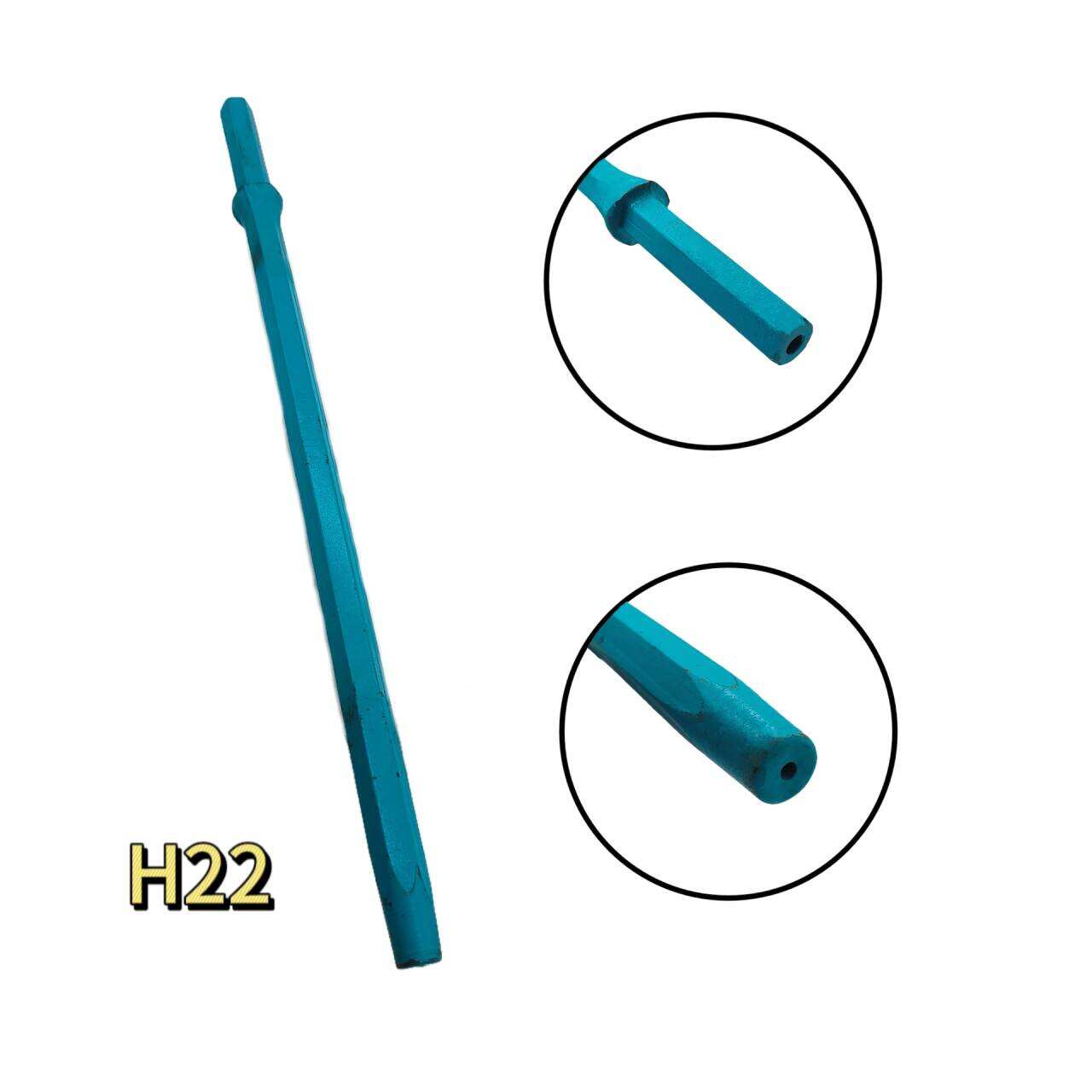

Thread Type |

Common thread types |

Packaging Details: |

Carton |

Payment Terms: |

T/T |

Supply Ability: |

Thread customization, color customization |

Description:

PCD anchor drill bit is a high-performance drilling tool designed for challenging materials such as reinforced concrete, abrasive rock, and other hard substrates. The cutting edge of the bit is embedded with polycrystalline diamond, one of the hardest materials known, which provides exceptional wear resistance and durability. This makes PCD anchor Drill Bits ideal for demanding drilling applications where conventional drill bits would wear out quickly. They are commonly used in construction, mining, and geotechnical engineering to create precise and clean holes for anchoring systems. The superior hardness and thermal stability of PCD ensure efficient drilling with reduced downtime for bit replacement.

Applications:

Anchor drill bit: used in coal mines, tunnels, and support nets.

Competitive Advantage:

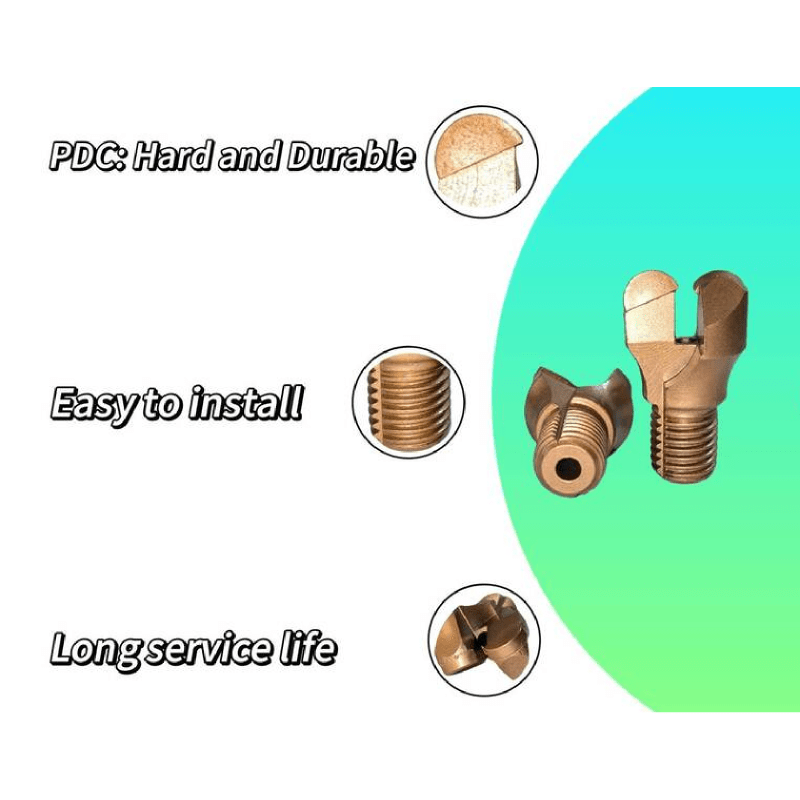

1.High wear resistance:

PDC cutting teeth are made of a composite of artificial diamond and cemented carbide. The hardness is second only to natural diamond and has excellent wear resistance.

2.High drilling speed:

PDC drill bits can achieve rapid drilling in soft to medium-hard formations, significantly improving drilling efficiency.

3.Long life:

Due to the high wear resistance of diamond, PDC drill bits have a long Service life and reduce the frequency of replacement.

4.Good stability:

The design focuses on stability, reduces downhole vibration, and reduces the risk of drilling tool damage.

5.Strong adaptability:

By adjusting the cutting tooth structure, PDC drill bits can adapt to a variety of formation conditions.