Professional water exploration drill concave PDC drill bit

PDC drill bit is a drill bit that uses polycrystalline diamond composite pieces as cutting teeth and is widely used in oil and gas drilling and geological exploration. Its high efficiency and durability make it an important tool in modern drilling operations.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Model Number: |

Concave type |

Certification: |

Provide |

Commercial terms of Products

Minimum Order Quantity: |

10 |

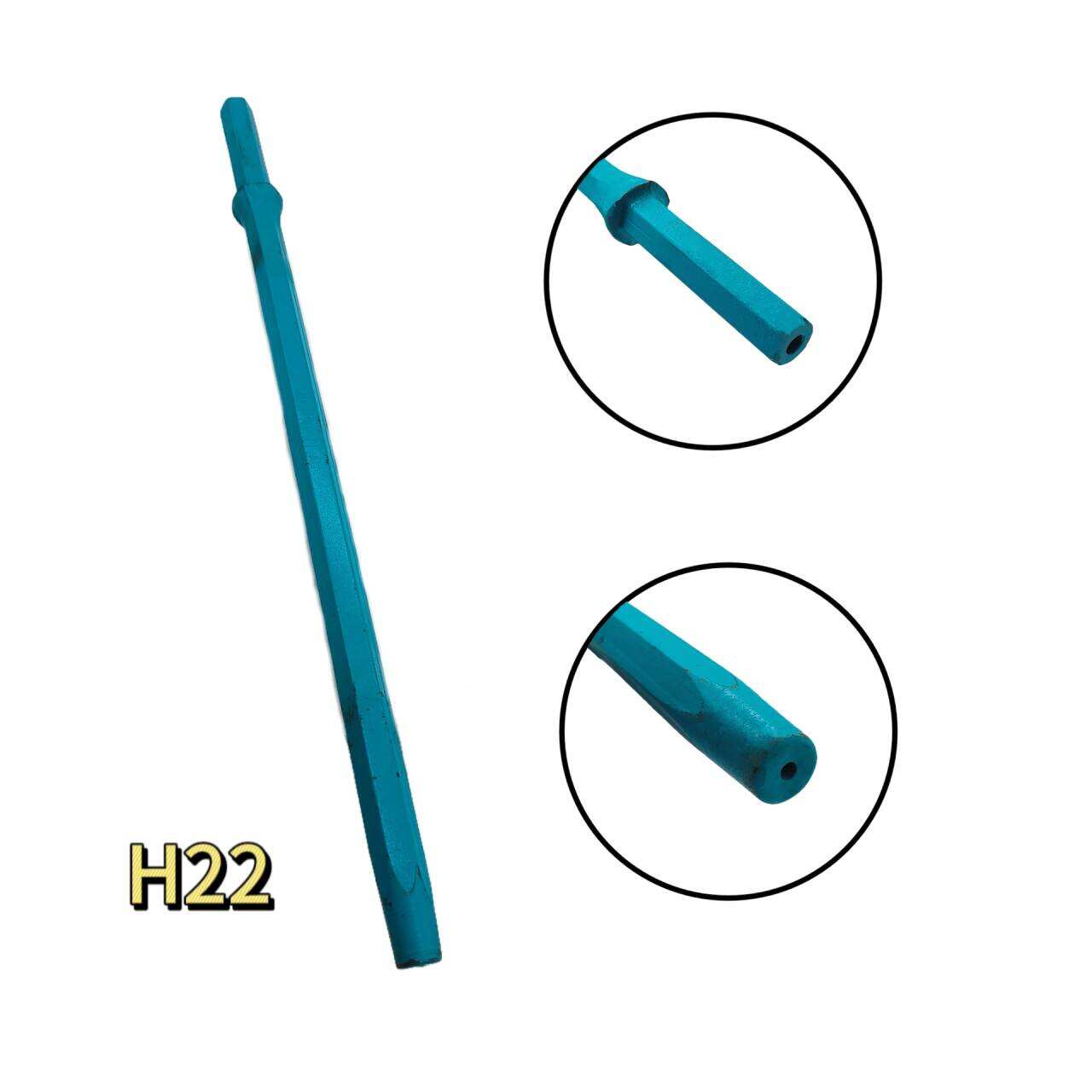

Thread Type |

Common thread types |

Packaging Details: |

Carton |

Payment Terms: |

T/T |

Supply Ability: |

Thread customization, color customization |

Specifications:

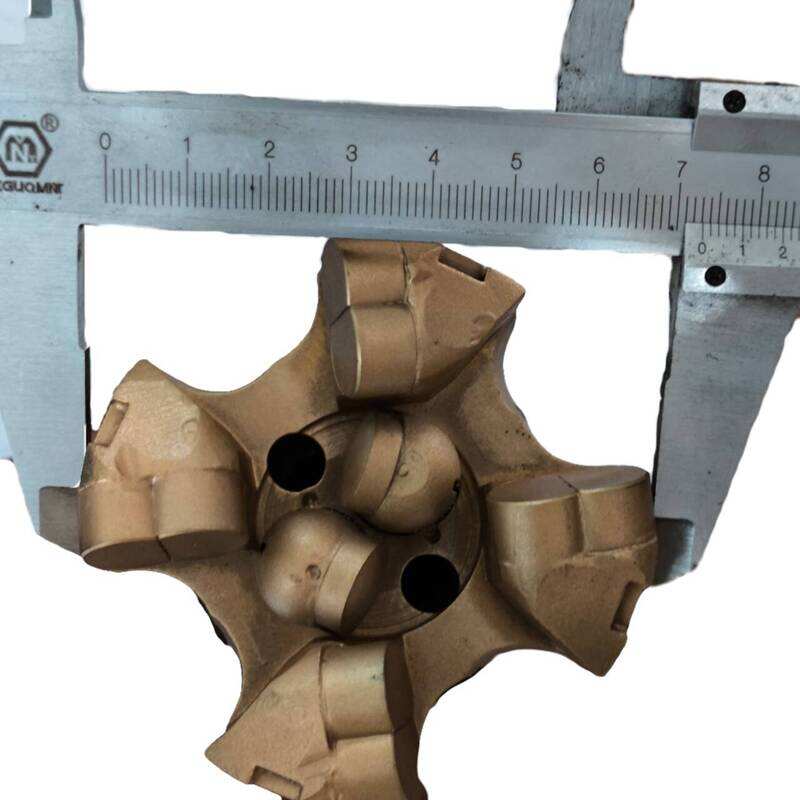

Concave 3-wing PDC drill bit |

50mm,55mm,60mm,65mm,75mm,85mm,94mm,113mm,133mm,140mm,153mm,173mm,183mm,193mm,200mm,215mm ~ 300mm |

Concave 4-wing PDC drill bit |

75mm,94mm,113mm,133mm,153mm ~ 200mm |

Concave 5-wing PDC drill bit |

133mm,153mm,173mm ~ 200mm |

Description:

PDC drill bit is a drill bit that uses polycrystalline diamond composite pieces as cutting teeth and is widely used in oil and gas drilling and geological exploration. Its high efficiency and durability make it an important tool in modern drilling operations.

Concave type: The PDC sheet has a surface layout, each wing has the same layout, and the drilling operation is on the same plane.

Applications:

1.Oil and gas drilling:

Widely used in oil and gas field development, especially in soft to medium-hard formations.

2.Geological exploration:

Used for geological drilling to obtain underground rock formation information.

3.Mining:

Used for blast hole drilling in mine drilling

Competitive Advantage:

1.High wear resistance:

PDC cutting teeth are made of a composite of artificial diamond and cemented carbide. The hardness is second only to natural diamond and has excellent wear resistance.

2.High drilling speed:

PDC Drill Bits can achieve rapid drilling in soft to medium-hard formations, significantly improving drilling efficiency.

3.Long life:

Due to the high wear resistance of diamond, PDC drill bits have a long Service life and reduce the frequency of replacement.

4.Good stability:

The design focuses on stability, reduces downhole vibration, and reduces the risk of drilling tool damage.

5.Strong adaptability:

By adjusting the cutting tooth structure, PDC drill bits can adapt to a variety of formation conditions.