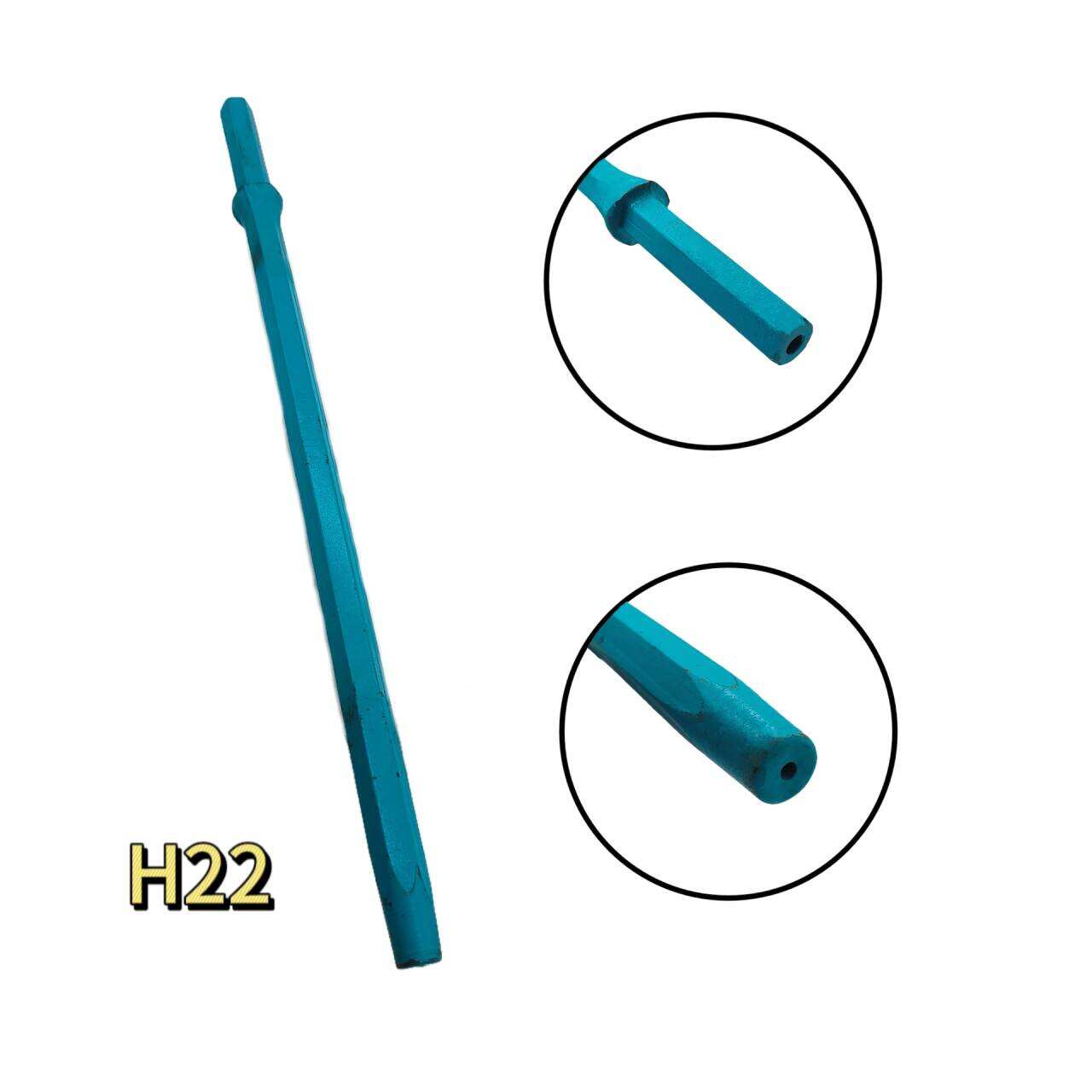

High quality angular PDC drill bits for a variety of applications

It evolved from the oil drill bit. The pieces on several wings are not distributed in a line, but point-to-point. The pieces on each wing are spatially complementary. The entire working surface is hit by teeth, there is no blind spot, and the teeth advance quickly.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Model Number: |

Arc angle type |

Commercial terms of Products

Minimum Order Quantity: |

10 |

Thread Type |

Common thread types |

Packaging Details: |

Carton |

Payment Terms: |

T/T |

Supply Ability: |

Thread customization, color customization |

Specifications:

Arc angle 3 wings: |

75mm,94mm,98mm,113mm,115mm,133mm,140mm,153mm。 |

Arc angle 4 wings: |

94mm,98mm,113mm,133mm,153mm |

Arc angle 5 wings |

Customized |

Arc angle 6 wings : |

Customized |

Description:

It evolved from the oil drill bit. The pieces on several wings are not distributed in a line, but point-to-point. The pieces on each wing are spatially complementary. The entire working surface is hit by teeth, there is no blind spot, and the teeth advance quickly.

Applications:

1.Oil and gas drilling:

Widely used in oil and gas field development, especially in soft to medium-hard formations.

2.Geological exploration:

Used for geological drilling to obtain underground rock formation information.

3.Mining:

Used for blast hole drilling in mine drilling

Competitive Advantage:

1.High wear resistance:

PDC cutting teeth are made of a composite of artificial diamond and cemented carbide. The hardness is second only to natural diamond and has excellent wear resistance.

2.High drilling speed:

PDC Drill Bits can achieve rapid drilling in soft to medium-hard formations, significantly improving drilling efficiency.

3.Long life:

Due to the high wear resistance of diamond, PDC drill bits have a long Service life and reduce the frequency of replacement.

4.Good stability:

The design focuses on stability, reduces downhole vibration, and reduces the risk of drilling tool damage.

5.Strong adaptability:

By adjusting the cutting tooth structure, PDC drill bits can adapt to a variety of formation conditions.