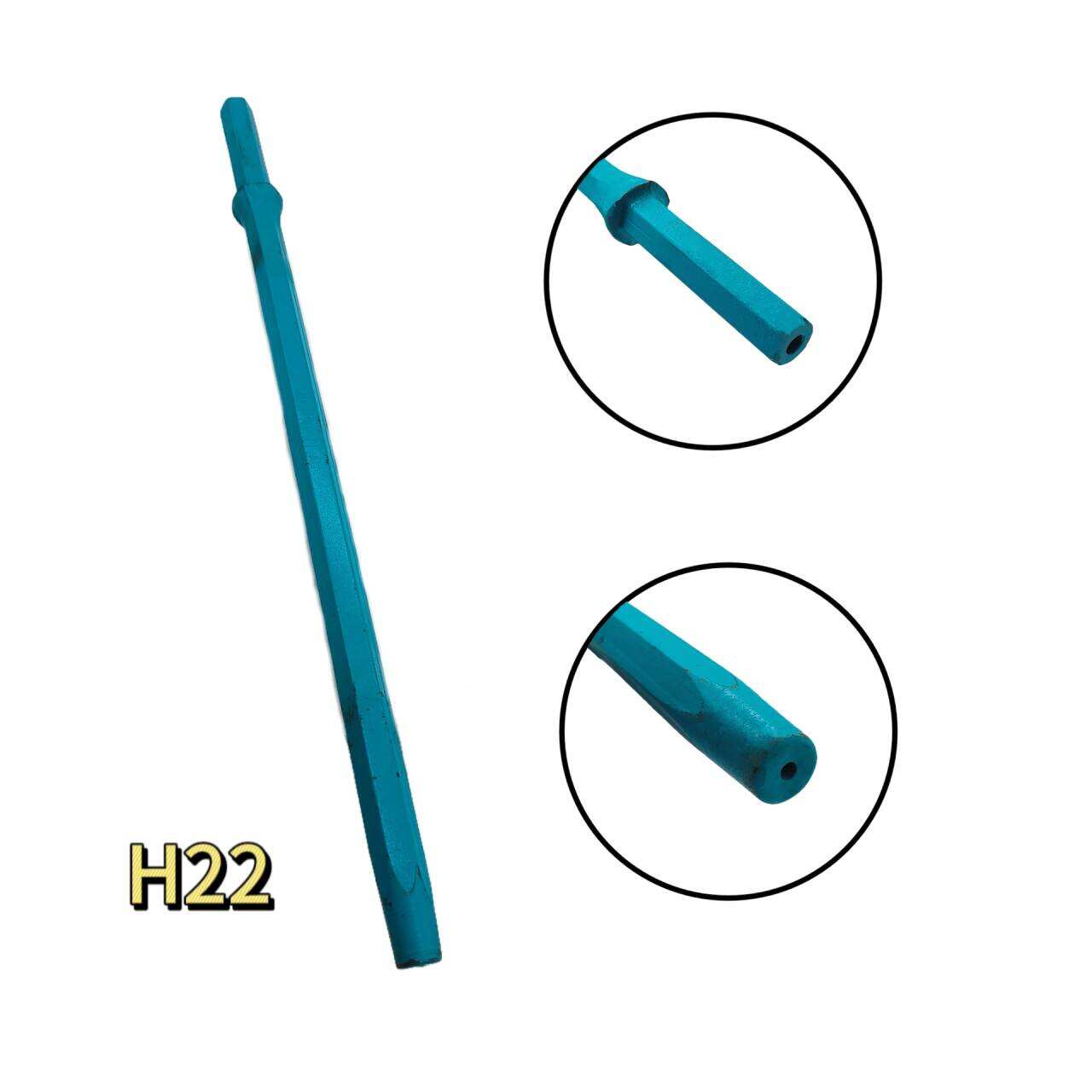

H19 H22 H25H Tapered drill rods for mining

A tapered drill rod is a key component used in drilling operations, particularly in mining, construction, and quarrying. It features a tapered design that provides a secure connection to drilling tools, such as tapered button bits, enhancing the stability and efficiency of the drilling process.

- Overview

- Recommended Products

Product general information

Place of Origin |

China |

Brand Name |

Realon |

Model Number |

H19 、H22 、H25 |

Processing Type |

Forging |

Commercial terms of Products

Productive Process |

Carburized,Heat-treatment |

Material |

23CrNi3Mo/55SiMnMo/Z708 |

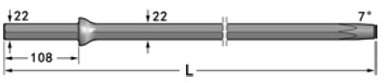

Shank |

H22x108±1mm, H25x159±1mm |

Length |

0.6m~8m |

Productive Process |

Heat-treatment |

Package |

Nude packing, Bundles, Tray, Plywood case |

Description

A tapered Drill Rod is a key component used in drilling operations, particularly in mining, construction, and quarrying. It features a tapered design that provides a secure connection to drilling tools, such as tapered button bits, enhancing the stability and efficiency of the drilling process. The tapered shape helps in better energy transfer during drilling, allowing for faster and more effective penetration of rock formations.

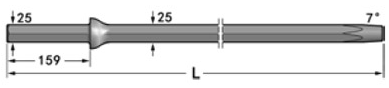

Tapered drill rods are typically made from high-quality alloy steel, ensuring strength, durability, and resistance to wear and corrosion. Their robust construction minimizes the risk of breakage and fatigue, making them suitable for challenging drilling conditions. The rods are available in various sizes and taper angles (e.g., 7°, 11°, 12°), allowing users to select the ideal fit for specific drilling equipment and tasks.

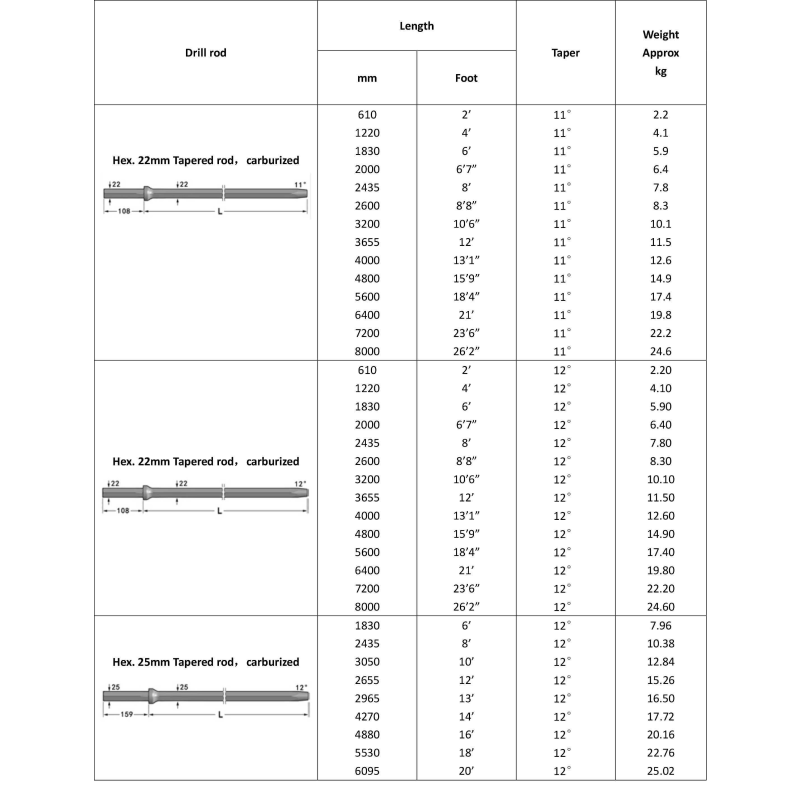

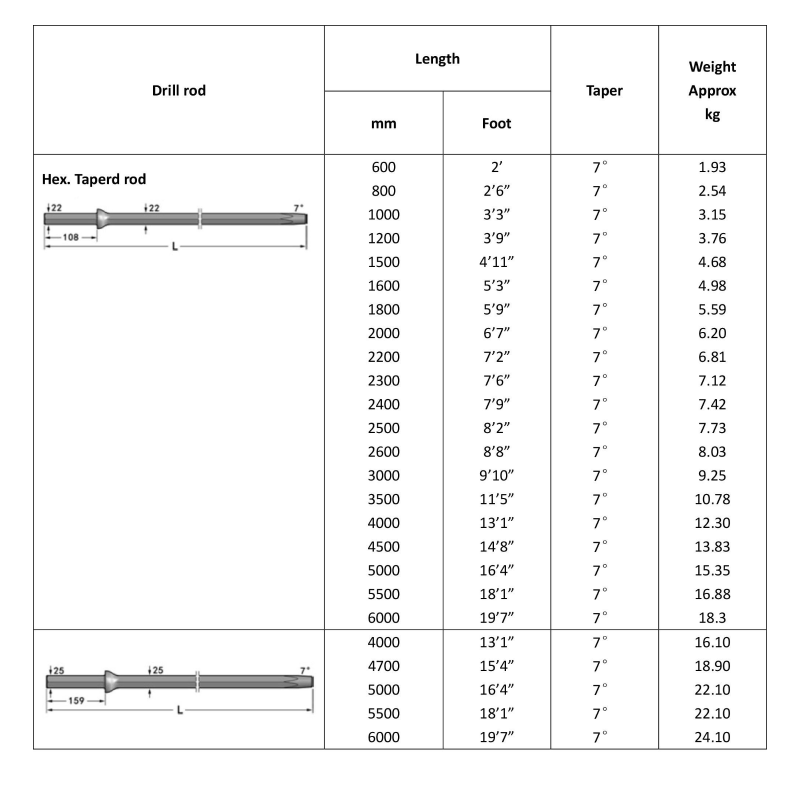

Specifications

Drill rod |

Length |

Taper |

Weight Approx kg |

|

mm |

Foot |

|||

|

Hex. Taperd rod

|

600 800 1000 1200 1500 1600 1800 2000 2200 2300 2400 2500 2600 3000 3500 4000 4500 5000 5500 6000 |

2’ 2’6” 3’3” 3’9” 4’11” 5’3” 5’9” 6’7” 7’2” 7’6” 7’9” 8’2” 8’8” 9’10” 11’5” 13’1” 14’8” 16’4” 18’1” 19’7” |

7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° 7° |

1.93 2.54 3.15 3.76 4.68 4.98 5.59 6.20 6.81 7.12 7.42 7.73 8.03 9.25 10.78 12.30 13.83 15.35 16.88 18.3 |

|

4000 4700 5000 5500 6000 |

13’1” 15’4” 16’4” 18’1” 19’7” |

7° 7° 7° 7° 7° |

16.10 18.90 22.10 22.10 24.10 |

Drill rod |

Length |

Taper |

Weight Approx kg |

|

mm |

Foot |

|||

|

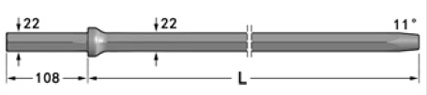

Hex. 22mm Tapered rod,carburized

|

610 1220 1830 2000 2435 2600 3200 3655 4000 4800 5600 6400 7200 8000 |

2’ 4’ 6’ 6’7” 8’ 8’8” 10’6” 12’ 13’1” 15’9” 18’4” 21’ 23’6” 26’2” |

11° 11° 11° 11° 11° 11° 11° 11° 11° 11° 11° 11° 11° 11° |

2.2 4.1 5.9 6.4 7.8 8.3 10.1 11.5 12.6 14.9 17.4 19.8 22.2 24.6 |

|

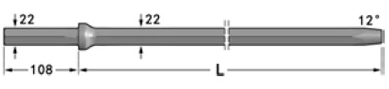

Hex. 22mm Tapered rod,carburized |

610 1220 1830 2000 2435 2600 3200 3655 4000 4800 5600 6400 7200 8000 |

2’ 4’ 6’ 6’7” 8’ 8’8” 10’6” 12’ 13’1” 15’9” 18’4” 21’ 23’6” 26’2” |

12° 12° 12° 12° 12° 12° 12° 12° 12° 12° 12° 12° 12° 12° |

2.20 4.10 5.90 6.40 7.80 8.30 10.10 11.50 12.60 14.90 17.40 19.80 22.20 24.60 |

|

Hex. 25mm Tapered rod,carburized

|

1830 2435 3050 2655 2965 4270 4880 5530 6095 |

6’ 8’ 10’ 12’ 13’ 14’ 16’ 18’ 20’ |

12° 12° 12° 12° 12° 12° 12° 12° 12° |

7.96 10.38 12.84 15.26 16.50 17.72 20.16 22.76 25.02 |

Applications

Tapered drill rods are widely used in mining, tunneling, quarrying and other fields. In mining, tapered drill rods are used for drilling blast holes and other drilling operations. In tunneling, tapered drill rods ensure the continuity and stability of the drilling process and are suitable for tunnel construction in hard rock formations. In the quarrying industry, tapered drill rods are used for the mining of ores such as stone, granite, marble, and are suitable for effective drilling in hard rock formations. Tapered drill rods are also used for foundation drilling, anchoring and other rock drilling tasks in construction to ensure the efficiency and accuracy of construction projects. In geotechnical drilling, tapered drill rods are used for geological exploration, collecting samples and data, and supporting construction and infrastructure planning. Overall, tapered drill rods are widely used in various drilling operations due to their stability, durability and high efficiency.

Competitive Advantage

Tapered drill rods have significant competitive advantages in mining, tunneling, quarrying and other fields. Their high hardness, high toughness and high wear resistance enable them to perform well in hard rock formations, ensuring the stability and efficiency of the drilling process. In addition, the design of tapered drill rods optimizes energy transfer, increases drilling speed, reduces equipment wear and extends Service life. In the production process, advanced heat treatment processes and strict quality control are used to ensure the high quality and reliability of the products. These advantages make tapered drill rods highly competitive in the market and meet the needs of various drilling operations for high-performance tools.