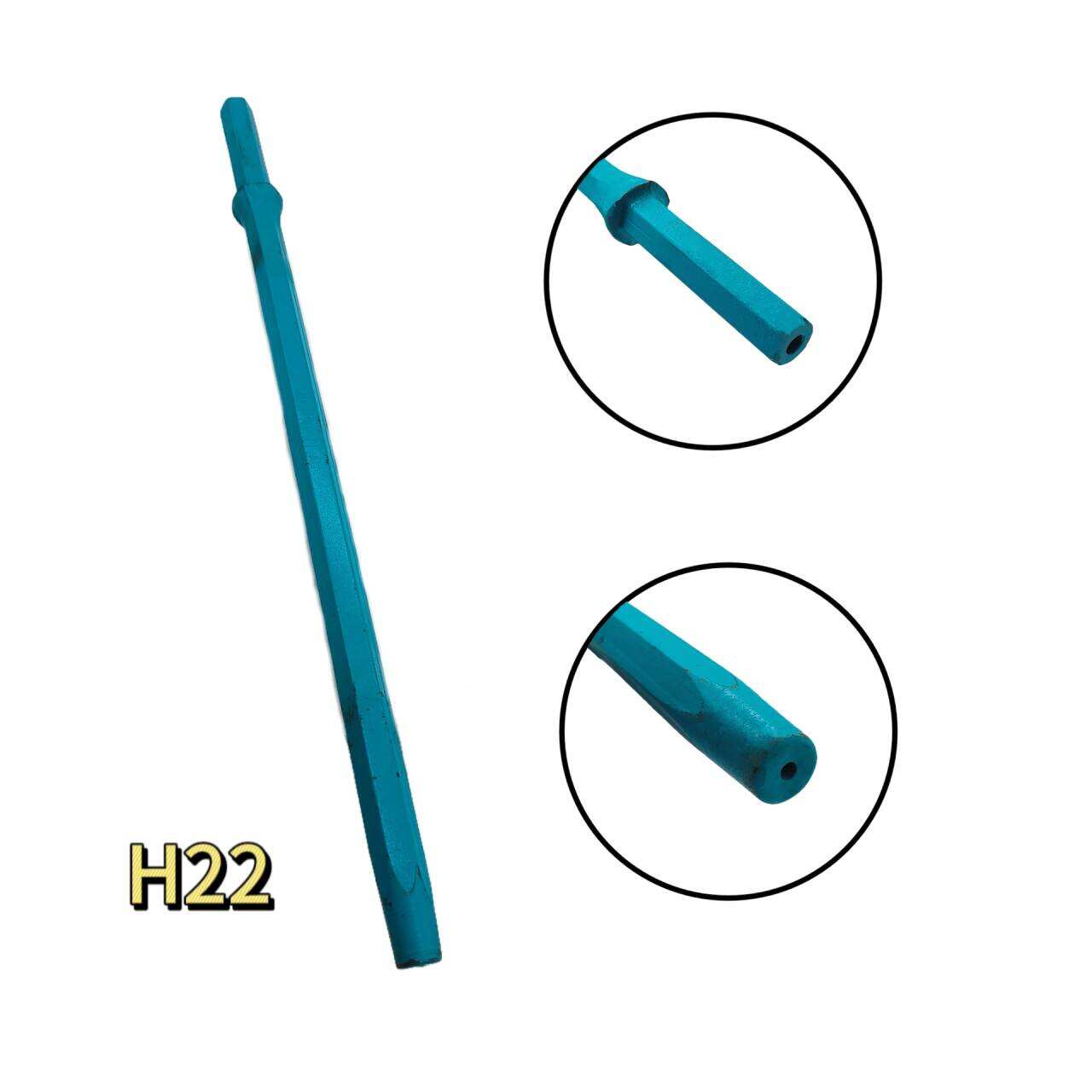

Dth Bits Dth Hammer Milling Button Drill Bit for Well Dth Hammer Bits

DTH (Down-The-Hole) drill bits are specialized tools used in drilling operations, particularly in mining, construction, and oil and gas exploration. They are a crucial component of the DTH drilling system, which involves using compressed air to operate the drilling mechanism.

- Overview

- Recommended Products

Product general information

Place of Origin: |

China |

Brand Name: |

Realon |

Aplication |

mining, construction, water well drilling, quarrying |

Processing Type |

Forging |

Commercial terms of Products

Minimum Order Quantity: |

10 |

Packaging Details: |

Plastic boxes, wooden boxes, etc. |

Delivery Time: |

10~15days |

Payment Terms: |

T/T |

Supply Ability: |

Provide |

Description:

DTH (Down-The-Hole) Drill Bits are specialized tools used in drilling operations, particularly in mining, construction, and oil

and gas exploration. They are a crucial component of the DTH drilling system, which involves using compressed air to operate the drilling mechanism.

Applications:

1.Mining: used for blasting holes, exploration holes, etc.

2.Construction engineering: used for foundation treatment, pile foundation drilling, etc.

3.Water conservancy engineering: used for wells, drainage holes, etc.

4.Geological exploration: used for core sampling, geological surveys, etc.

Specifications:

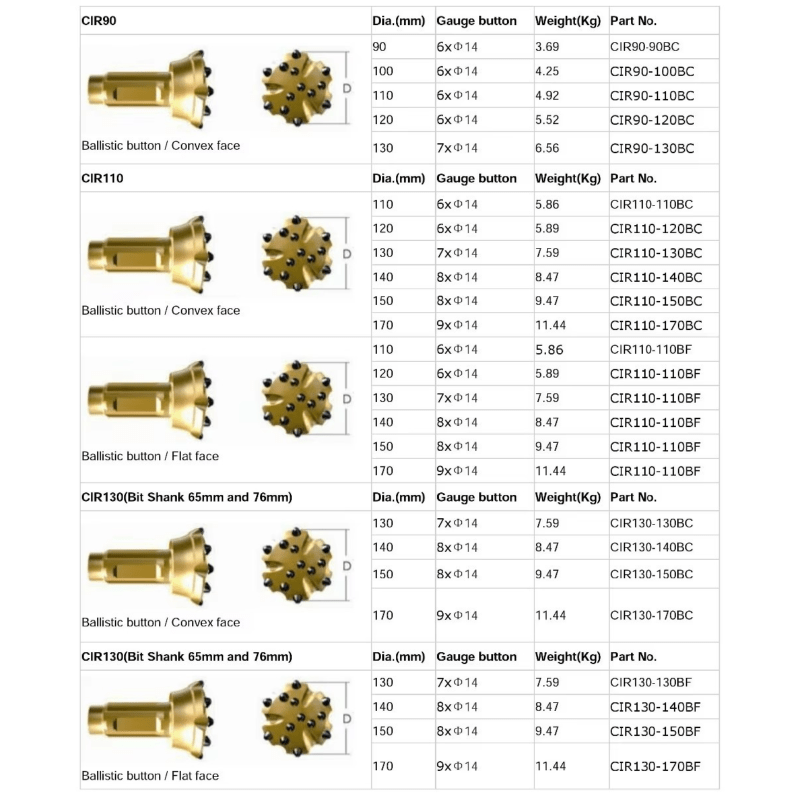

DTH Hammer model |

DTH drill bit size |

Application scenario |

CIR50 |

50mm/55mm

|

Applicable to early oil exploration |

CIR65 |

65mm/70mm |

|

CIR76 |

76mm/80mm |

Quarry Determined by the amount of charge Purpose: drilling blast holes, blasting mountains, mining stones. Drilling depth is 15~20m+ |

CIR90 |

90~130mm |

|

CIR110 |

110~150mm |

|

CIR130 |

130~170mm

|

水井 打孔深度100m+ |

CIR150 |

150~200mm |

|

CARBIDE BUTTON SHAPE |

|

Domed/Round Button |

|

Parabolic/Semi-Ballistic Button |

|

|

Ballistic Button |

Competitive Advantage

1. Wide range of uses: DTH drill bits are designed for drilling deep and precise holes in hard rock formations. They are often used in applications where traditional drilling methods are less efficient.

2. Professional design: These drill bits are made of durable materials such as tungsten carbide blades, steel or other carbides to withstand the high impact and wear encountered during drilling.

3. High efficiency: They provide high drilling efficiency and penetration rate, allowing for faster and more efficient drilling compared to traditional methods.

4. Strong compatibility: DTH drill bits are compatible with a variety of DTH hammers and drill rigs, ensuring flexibility and adaptability in different drilling operations.

5. Performance optimization: These drill bits are designed and engineered to optimize drilling performance, minimize downtime, and maximize the life of the drill bit.

6. Cost-effectiveness: Although the initial cost may be higher, DTH drill bits are cost-effective due to their durability and efficiency in challenging drilling environments.