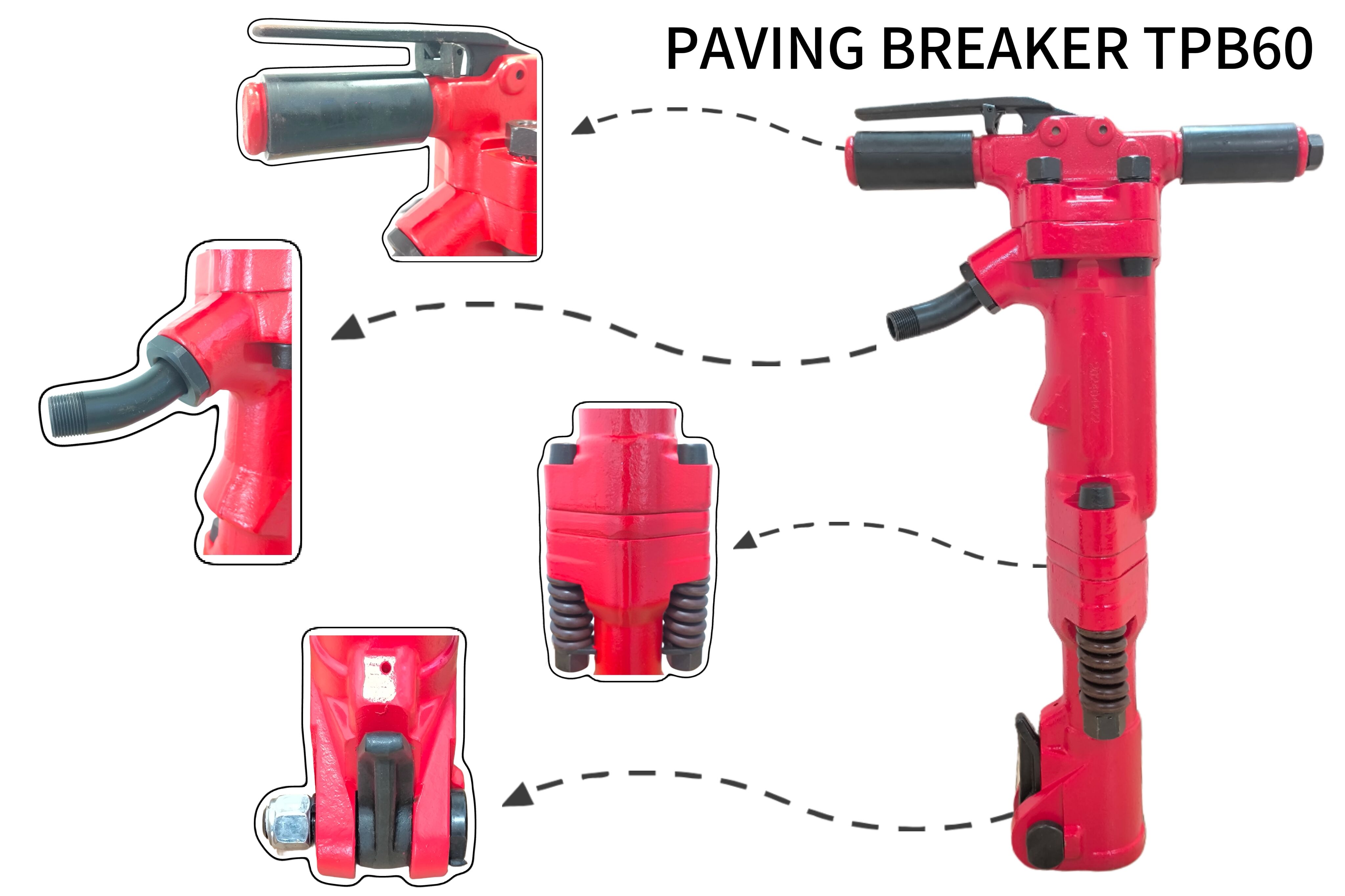

pneumatic breaker

A pneumatic breaker, also known as a pneumatic hammer or air hammer, is a powerful demolition tool that harnesses compressed air to deliver high-impact force for breaking hard materials. This versatile equipment operates through a reciprocating piston mechanism that converts air pressure into mechanical energy, creating rapid and forceful strikes against the target surface. The tool consists of a main body housing the piston assembly, an air inlet valve, a trigger mechanism, and interchangeable working tools such as chisels or points. Modern pneumatic breakers feature ergonomic designs with vibration-dampening systems and adjustable power settings, making them suitable for various applications. These tools excel in construction, mining, road work, and demolition projects, efficiently breaking concrete, asphalt, rock, and other dense materials. The pneumatic system ensures consistent power delivery and reliable performance, while the absence of electrical components makes them safe for use in wet conditions. Advanced models incorporate features like automatic lubrication systems and quick-change tool holders, enhancing operational efficiency and reducing maintenance requirements.