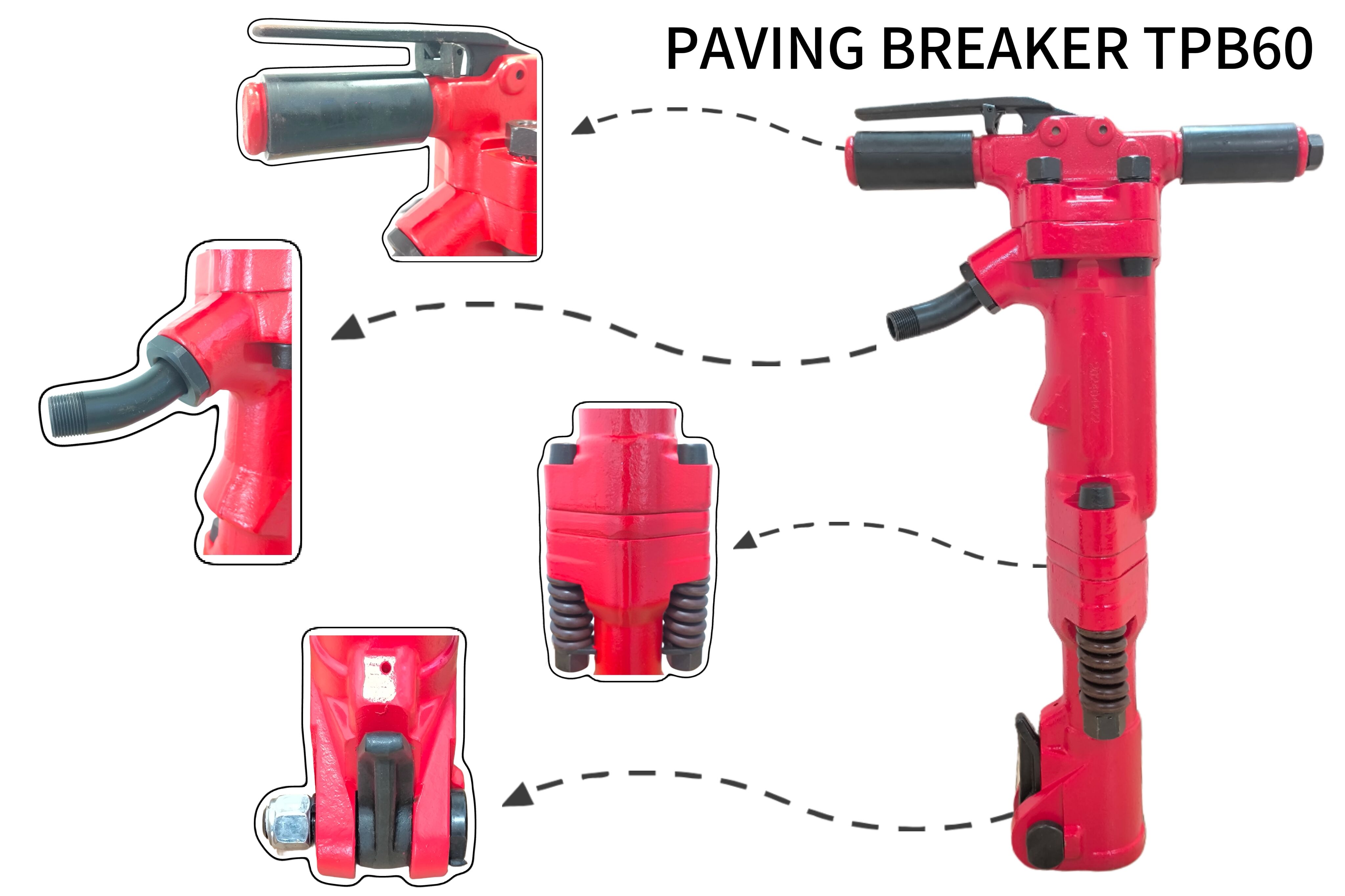

pneumatic breaker hammer

The pneumatic breaker hammer is a powerful demolition tool that harnesses compressed air to deliver high-impact force for breaking concrete, asphalt, and other hard materials. This versatile equipment combines robust construction with precision engineering, featuring a piston-driven mechanism that converts air pressure into mechanical energy. The tool consists of a main body housing the air-driven piston, a trigger mechanism for operation control, and interchangeable chisels or points for different applications. Operating at pressures typically between 90 and 120 PSI, these hammers deliver consistent power output while maintaining operational efficiency. The design incorporates vibration-dampening systems and ergonomic handles to enhance user comfort during extended use. Modern pneumatic breaker hammers often include features such as automatic lubrication systems, quick-change tool holders, and noise reduction technology. These hammers are available in various sizes and power ratings, from lightweight models for precise work to heavy-duty versions for demanding industrial applications. The tool's reliability in challenging conditions, combined with its relatively simple mechanical design, makes it a cornerstone of construction, mining, and road maintenance operations.