pneumatic air breaker

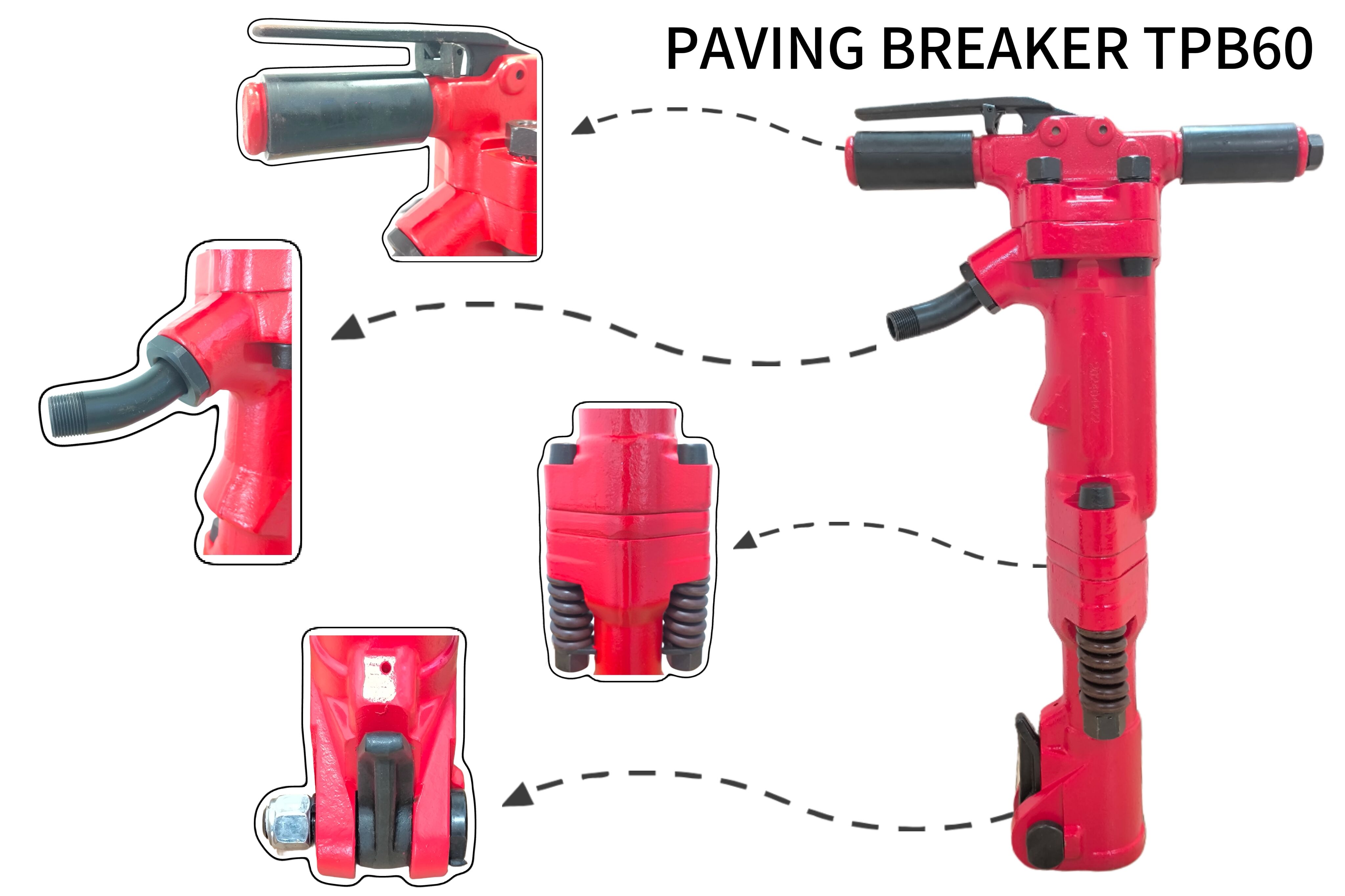

A pneumatic air breaker is a powerful demolition tool that harnesses compressed air to deliver high-impact force for breaking various materials. This essential construction equipment consists of a robust housing, an internal piston mechanism, and a specialized chisel or bit attachment. The tool operates by converting compressed air energy into mechanical force, creating rapid reciprocating motion that generates powerful striking impacts. The breaker's design typically incorporates ergonomic handles, vibration-dampening systems, and adjustable air pressure controls for optimal performance. These tools are engineered to withstand demanding conditions while maintaining consistent breaking power across different applications. Modern pneumatic breakers feature advanced air flow management systems that enhance efficiency and reduce air consumption. The tools are available in various sizes and power ratings, ranging from lightweight models for precision work to heavy-duty versions for challenging demolition tasks. Their versatility makes them indispensable in construction, road work, mining, and renovation projects. The breaker's simple yet effective design ensures reliable operation with minimal maintenance requirements, while its air-powered nature eliminates the need for electrical connections in potentially hazardous environments.