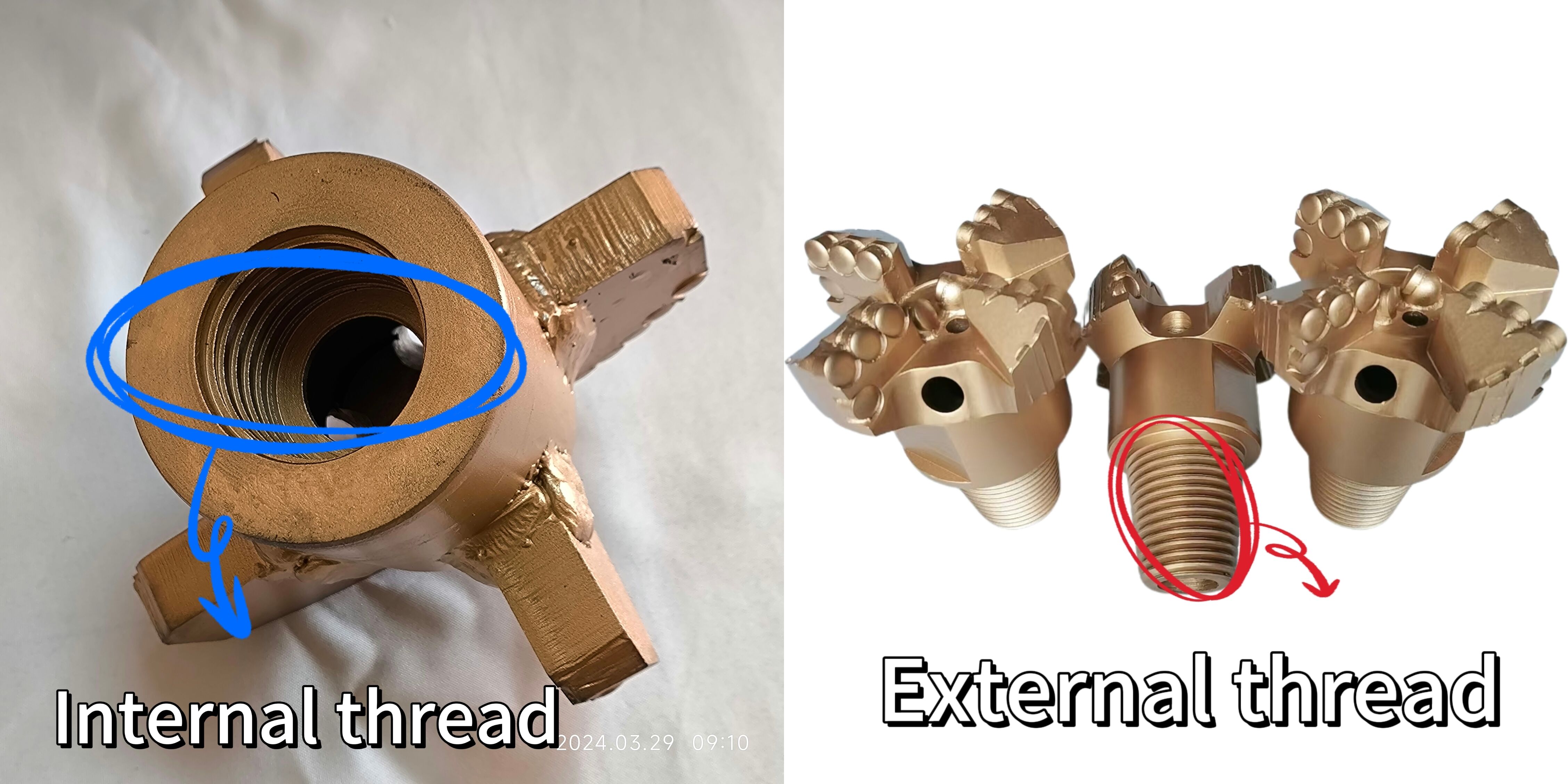

pdc diamond bit

The PDC (Polycrystalline Diamond Compact) diamond bit represents a revolutionary advancement in drilling technology, combining durability with exceptional cutting efficiency. This sophisticated drilling tool features synthetic diamond particles bonded together under high pressure and temperature conditions, creating an incredibly hard and wear-resistant cutting surface. The bit consists of multiple PDC cutters mounted on a steel body, strategically positioned to optimize drilling performance and material removal. The design incorporates advanced hydraulics that efficiently remove cuttings and cool the bit during operation, preventing overheating and ensuring consistent performance. PDC diamond bits excel in various applications, from oil and gas exploration to mining operations and construction projects. They are particularly effective in drilling through medium to hard formations, maintaining superior penetration rates while delivering exceptional hole quality. The bit's engineered structure includes carefully calculated blade configurations and cutter placements that enhance stability and reduce vibration during operation. Modern PDC bits often feature specialized geometries and cutting structures tailored to specific formation types, making them highly versatile tools for diverse drilling conditions. The technology behind these bits continues to evolve, with manufacturers incorporating innovative features such as enhanced thermal stability, improved impact resistance, and optimized cutting angles to maximize drilling efficiency and bit life.