down hole hammer bits

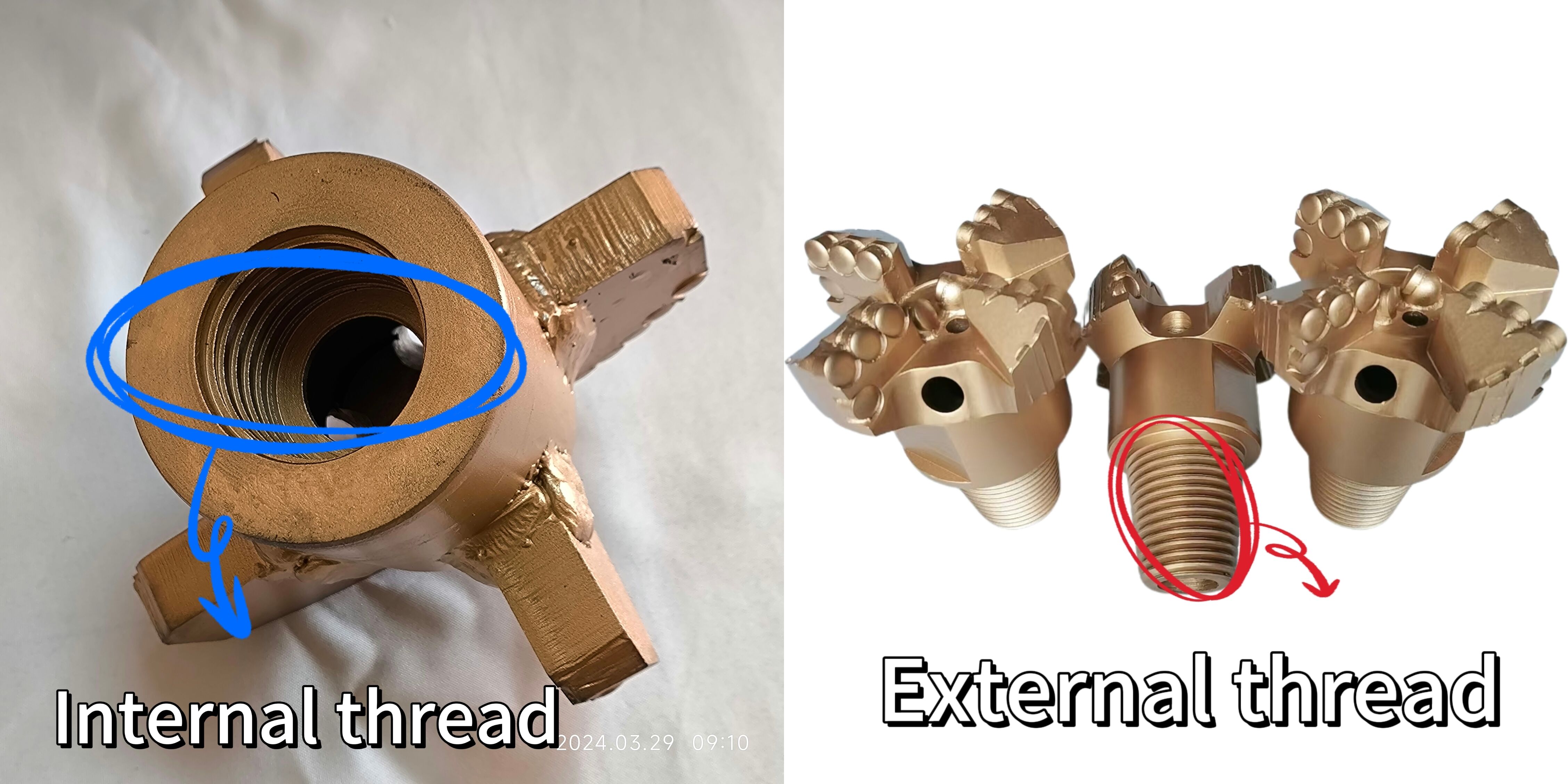

Down hole hammer bits represent a crucial advancement in drilling technology, combining robust engineering with precision performance for various drilling applications. These specialized tools consist of a hammer mechanism integrated with carbide buttons or inserts, designed to deliver powerful percussion force directly to the rock formation. The bits operate through a combination of rotation and high-frequency impact, powered by compressed air that drives the internal piston. This dual action allows for efficient penetration of hard rock formations while maintaining excellent hole straightness. The design typically incorporates air channels that serve multiple purposes: driving the hammer mechanism, clearing debris from the hole, and cooling the bit during operation. Modern down hole hammer bits feature sophisticated tungsten carbide button patterns optimized for specific rock conditions, with button shapes and sizes carefully engineered to maximize drilling efficiency. The bits are manufactured using high-grade steel bodies treated for enhanced durability, with premium grade carbide inserts that resist wear in the most demanding conditions. These tools find extensive application in mining exploration, water well drilling, construction, and quarrying operations, where their ability to maintain high penetration rates in hard rock formations makes them indispensable.