polycrystalline diamond drill bits

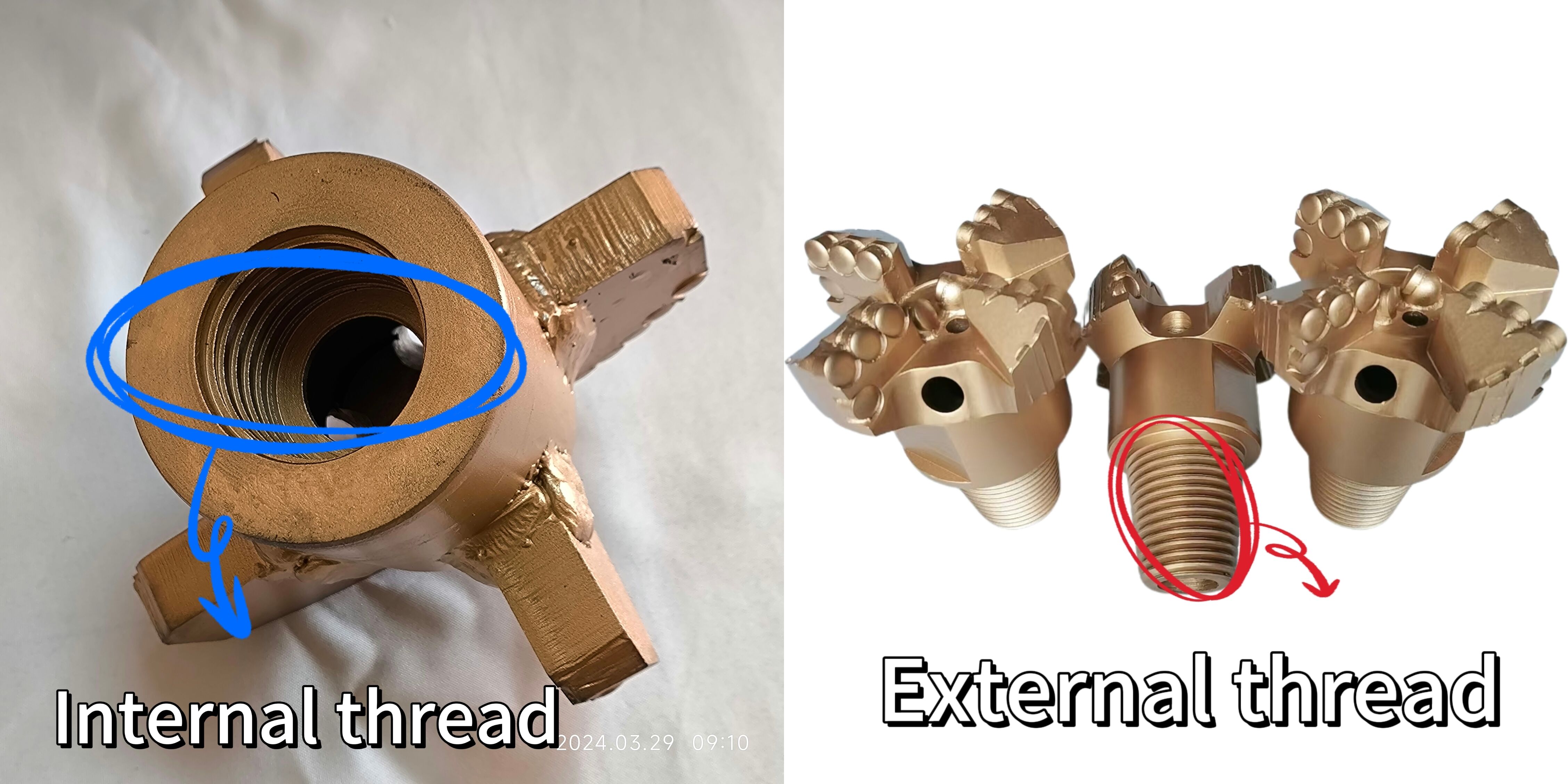

Polycrystalline diamond drill bits represent a revolutionary advancement in drilling technology, combining superior hardness with exceptional wear resistance. These cutting-edge tools feature multiple diamond crystals that are synthetically bonded under high pressure and temperature conditions, creating a robust cutting structure. The bits are engineered with strategically positioned diamond cutters on a tungsten carbide substrate, enabling them to maintain sharpness and structural integrity even under extreme drilling conditions. These drill bits excel in applications requiring precision and durability, particularly in oil and gas exploration, mining operations, and construction projects. The unique design allows for enhanced heat dissipation and improved debris removal, significantly reducing the risk of thermal damage and ensuring consistent performance. With their ability to drill through the hardest formations, including granite, basalt, and other abrasive materials, polycrystalline diamond drill bits have become indispensable in modern drilling operations. Their advanced cutting geometry and optimized fluid channels contribute to faster penetration rates and extended bit life, ultimately leading to more efficient and cost-effective drilling projects.