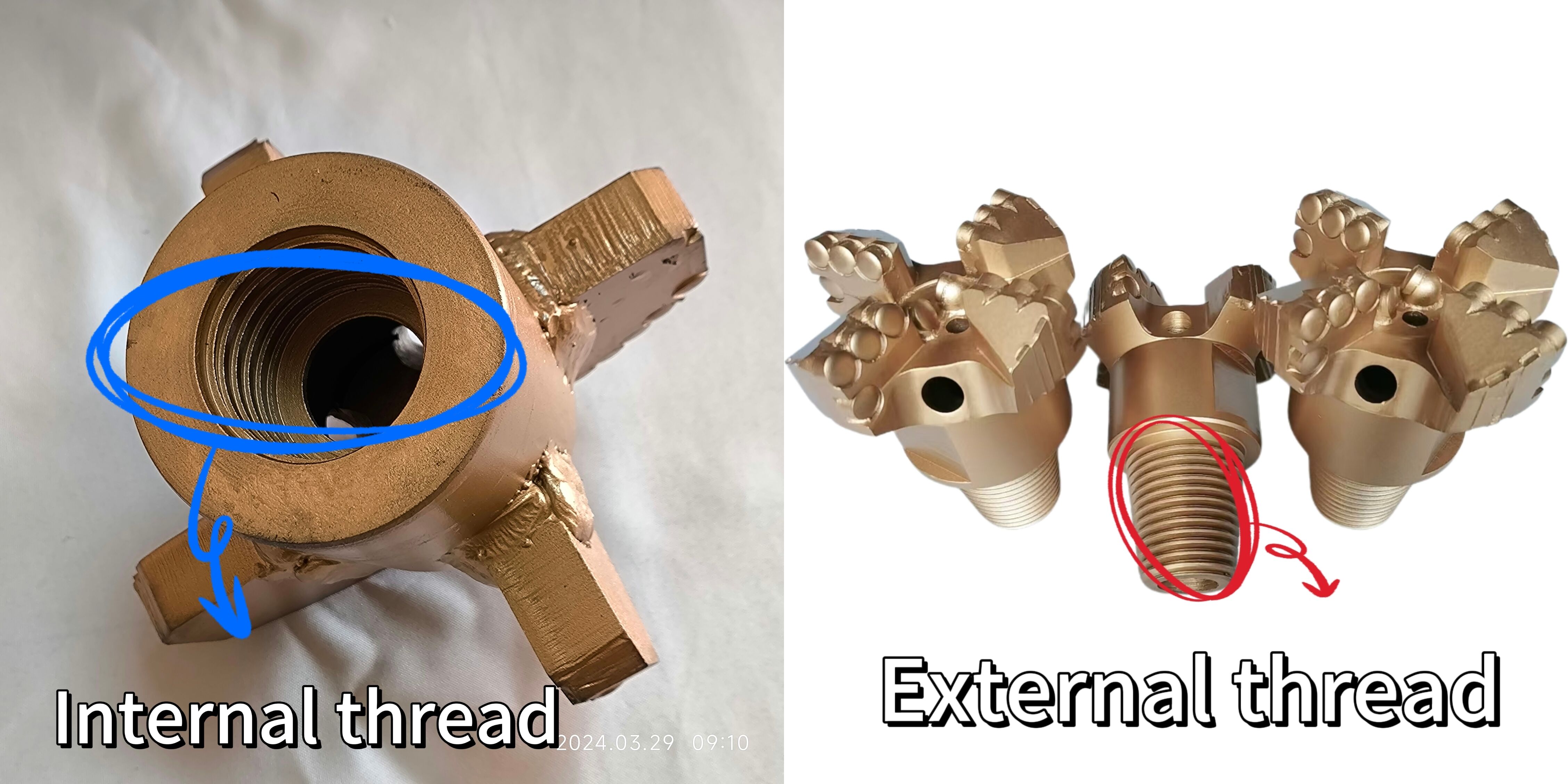

pdc drill bit

The PDC (Polycrystalline Diamond Compact) drill bit represents a revolutionary advancement in drilling technology, combining durability with exceptional cutting efficiency. This sophisticated drilling tool features synthetic diamond cutters that are strategically mounted on a tungsten carbide body, creating a robust and reliable drilling solution. The PDC bit's design incorporates multiple cutting elements arranged in a specific pattern to optimize drilling performance across various formation types. Each diamond cutter is engineered to withstand extreme temperatures and pressures while maintaining sharp cutting edges throughout extended operations. The bit's body includes carefully designed fluid channels that facilitate efficient cooling and debris removal during drilling operations. These bits have become increasingly popular in both oil and gas exploration and mining operations due to their superior performance characteristics. The technology behind PDC bits allows for faster penetration rates, longer bit life, and more precise directional control compared to traditional roller cone bits. They excel in maintaining borehole stability and delivering consistent performance in both soft and medium-hard formations. The bits feature advanced hydraulic designs that optimize fluid flow, ensuring effective cooling of the cutting elements and efficient removal of drilling cuttings. Modern PDC bits also incorporate sophisticated geometry calculations in their design, allowing for better weight distribution and more efficient cutting action across the entire bit face.