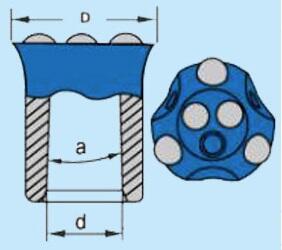

industrial rock drill

Industrial rock drills are sophisticated pieces of equipment designed for efficient rock penetration and excavation across various applications. These powerful tools combine advanced mechanical engineering with robust construction to deliver reliable performance in demanding conditions. Modern industrial rock drills utilize percussion and rotation mechanisms to effectively break through hard rock formations. They feature high-powered motors, typically powered by compressed air, hydraulic systems, or electricity, capable of generating substantial force for drilling operations. The design incorporates specialized drill bits and robust steel components that withstand extreme pressure and wear. These machines come equipped with advanced cooling systems to manage operational temperatures and dust suppression mechanisms to maintain workplace safety. Industrial rock drills are available in various configurations, including handheld units for precise work, mounted systems for large-scale operations, and automated drilling rigs for continuous production. They integrate sophisticated control systems that allow operators to adjust drilling parameters such as speed, pressure, and depth with high precision. The technology encompasses features like anti-vibration systems, ergonomic designs for operator comfort, and safety mechanisms that prevent equipment damage and ensure worker protection. These drills serve essential roles in mining, construction, quarrying, and civil engineering projects, making them indispensable tools in modern industrial operations.