drill bit well

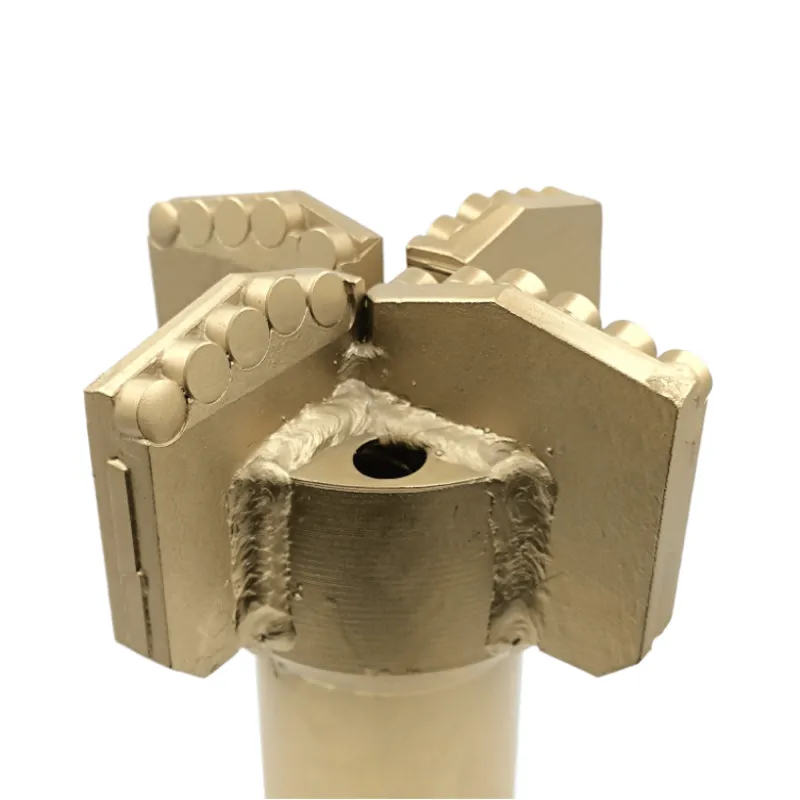

A drill bit well represents a sophisticated integration of cutting-edge drilling technology and precision engineering, designed to create efficient and reliable boreholes in various geological formations. This advanced drilling system combines robust mechanical components with innovative cutting mechanisms to achieve optimal penetration rates while maintaining borehole stability. The well structure typically incorporates multiple drill bit types, including roller cone bits, diamond bits, and PDC (Polycrystalline Diamond Compact) bits, each specially selected based on the formation characteristics and drilling objectives. The system features advanced hydraulic systems that facilitate efficient cuttings removal and bit cooling, while sophisticated sensors provide real-time data about drilling parameters and formation properties. These wells are engineered to withstand extreme pressures and temperatures, incorporating specialized materials and design features that ensure longevity and performance in challenging environments. The versatility of drill bit wells makes them indispensable in various applications, from oil and gas exploration to geothermal drilling and mineral extraction, offering consistent performance and reliability across diverse geological conditions.